How-To Modify your KCT-11 to Spin!

WARNING! Be extremely careful if you decide to modify your keychain turbos! We are not responsible for any damages, injuries, loss of limbs, or life. Always wear appropriate safety gear, follow safety instructions supplied with your power tools, and use common sense! Obviously any modifications to your keychain turbos may exceed the design and/or theoretical structural integrity causing premature failure thus voiding factory warranty.

Download Video (TurboKeychain.wmv)

Left is a stock KCT-11, Right is a modified KCT-11 to spin.

Upon receiving your package, you should have a KCT-11 and a compressor card.

Firmly press on the impeller blade, the backplate is held in place by some rubber cement-type glue and should pop off.

You should have three pieces, the compressor housing, impeller blades, and backplate.

As we can see the compressor housing is very restrictive, especially up near the output.

WARNING! Metal gets HOT! A dremel works nicely to hone out the inside of the compressor.

You can see the difference between the stock and the honed out housing

There's also plenty of room for the impeller blade to spin within the housing.

The impeller, obviously the eye-tab on the right will need to be shaved off. Otherwise it will be seriously off balance.

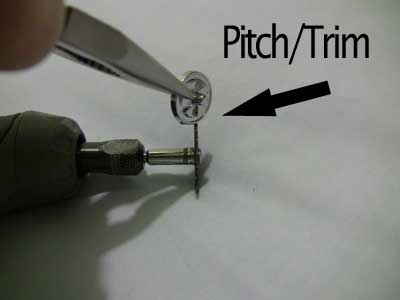

I've decided to make 45 degree angular cuts in the impeller. A lower pitch should cause the impeller to spin faster at a lower volume of air. A higher pitch should allow more volume of airflow but may result in a slower impeller spin. If hooking up to an air compressor - go for a higher pitch since you need as little restriction as possible.

Using about a #60 drill bit size (found at a hardware store such as Ace), drill directly into the center of the impeller. Don't worry if you are off by a fraction of a millimeter, you can always balance the impeller by shaving some material off from one side.

Now it's time for the backplate modifications.

You will need to shave some of the spacer to allow more room for the impeller to freewheel inside the housing.

Using the same drill bit, drill a hole through the spacer. This will be for the bearing.

The hole you just drilled.

A paper clip - this will act as our bearing.

Cut a piece and bend it into an L shape.

Thread your newly made bearing through the hole you drilled in the spacer, then apply hot glue. (Solder and/or super glue also works.)

Place the impeller onto the bearing shaft, inspect how much "play" you feel is appropriate. You may need to dab some hot glue or solder on the backside of the impeller wheel, and the front side you could simply bend the bearing shaft to keep the impeller wheel from sliding forward and impacting the compressor housing once assembled. Take your time on this step!

Assembled backplate, bearing shaft, and impeller wheel. It should spin freely with no wobble or resistance!

Insert the assembly into the compressor housing. You could temporarily hold or tape it in place for some low level testing. Once you are happy, you could apply rubber-cement, or hot glue. If you are real confident, you could use some sort of super glue or cold weld.

You are done! Hopefully you have successfully modded your KCT-11 to spin simply by blowing through the outlet, or inlet. If you blow hard enough or use an air compressor it should spin fast enough to create a real turbo sound.